Facilities, resources, and equipment are not just about compliance – they’re the foundation of quality training delivery.

Under the Standards for RTOs 2025, Standard 1.8 requires RTOs to demonstrate that every training product is delivered with facilities, resources, and equipment that are:

- Fit-for-purpose

- Safe

- Accessible

- Sufficient

This applies whether resources are owned by the RTO or provided by third parties, employers, or community organisations.

Breaking Down the Key Terms

Fit-for-Purpose

Resources must align with training.gov.au requirements. Students must be able to demonstrate all performance criteria, knowledge, evidence, and foundation skills.

👉 Example: In CPC30220 Certificate III in Carpentry, units require access to scaffolding, roofing tools, and WHS gear. If these aren’t available, training isn’t “fit-for-purpose.”

Safe

Facilities and equipment must meet WHS laws and industry standards, and safety must be maintained over time.

👉 Example: Outdated scaffolding, broken tools, or PPE in poor condition are not compliant. Students must also be inducted into safe use.

Accessible

Students must have practical access, not just theoretical access.

👉 Example: If 25 carpentry students share 5 nail guns, students are waiting around instead of learning → not accessible.

For online RTOs, this means ensuring all students have the required software, systems, and licences.

Sufficient

The quantity of resources must match student numbers.

👉 Example: If a carpentry intake has 25 students, the RTO must have enough equipment for 25 learners to complete all tasks — or an effective rotation system that ensures each student has equal opportunity.

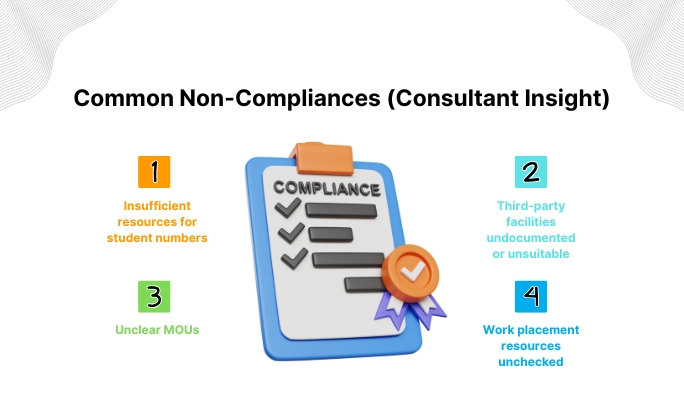

Common Non-Compliances (Consultant Insight)

From my 15+ years as a compliance consultant, I see these issues most often:

- Insufficient resources for student numbers

- TAS lists 25 students, but only 12 toolkits are available.

- Students can’t complete tasks → non-compliance.

- Third-party facilities are undocumented or unsuitable

- MOUs were signed with workplaces, but no verification of resources.

- Example: aged care placements without manual handling equipment.

- Unclear MOUs

- Agreements don’t specify who maintains, supplies, or replaces

- At the audit, RTO can’t show accountability.

- Work placement resources unchecked

- RTO assumes employers have the correct facilities.

- No site checks → unsafe or insufficient resources discovered too late.

Case Study – Carpentry RTO Audit

Audit Context:

An RTO delivered CPC30220 Certificate III in Carpentry to 25 students.

Findings:

- TAS claimed full resource availability.

- Onsite inspection found only 12 toolkits and 2 scaffolding sets.

- Students reported waiting long periods to use equipment.

- Placement MOUs with employers didn’t specify PPE responsibility.

Outcome:

- ASQA issued non-compliance for insufficient, inaccessible, and unclear resources.

- RTO was required to:

- Purchase additional toolkits and scaffolding.

- Update MOUs to assign responsibility for resources.

- Conduct placement site checks before sending students.

Result: Rectification accepted. Student training improved and compliance risks reduced.

Self-Assurance Checklist

Ask yourself:

Have we listed all facilities/resources for each training product using training.gov.au?

Have we listed all facilities/resources for each training product using training.gov.au?

Do we keep an equipment register by qualification?

Do we keep an equipment register by qualification?

Are resources fit-for-purpose for the skills required?

Are resources fit-for-purpose for the skills required?

Are they safe (regular inspections, WHS compliant)?

Are they safe (regular inspections, WHS compliant)?

Are they accessible for all students during training and assessment?

Are they accessible for all students during training and assessment?

Are they sufficient for class sizes?

Are they sufficient for class sizes?

Do our MOUs with third parties specify resource responsibilities?

Do our MOUs with third parties specify resource responsibilities?

Do we check work placement sites for sufficiency and safety before students start?

Do we check work placement sites for sufficiency and safety before students start?

FAQs on Standard 1.8

No. Equipment can be provided by third parties (e.g., employers), but the RTO remains accountable for suitability, safety, and sufficiency.

- Students cannot complete required tasks.

- RTO risks major non-compliance.

- ASQA may restrict or suspend delivery.

- Site visits to inspect facilities.

- Interviews with students about access.

- Review of equipment registers, MOUs, and maintenance logs.

Yes. If delivery requires software, platforms, or systems, the RTO must ensure all students have access.

- Written agreements with employers.

- WHS induction for students.

- Verification of workplace resources.

- Clear supervision arrangements.

Facilities and resources are more than equipment lists — they are a direct reflection of your RTO’s quality and compliance culture. By ensuring they are fit-for-purpose, safe, accessible, and sufficient, you protect students, industry trust, and your RTO’s registration.

Disclaimer:

The information presented on the VET Resources blog is for general guidance only. While we strive for accuracy, we cannot guarantee the completeness or timeliness of the information. VET Resources is not responsible for any errors or omissions, or for the results obtained from the use of this information. Always consult a professional for advice tailored to your circumstances.